16.02.2023 / Members News

First horizontal, six-nozzle Pelton turbine – Voith Hydro sets new benchmarks at Gerlos 1 power plant

- Voith Hydro reaches milestone in Pelton technology

- At the Gerlos 1 pumped storage power plant in Tyrol, energy utility Verbund replaces four turbines by one thanks to new concept

- Great potential for upgrading hydropower plants worldwide

GERMANY/AUSTRIA. The trial operation of the first horizontal, six-nozzle Pelton turbine at the Gerlos 1 power plant has been running successfully for over two months now, and is setting new benchmarks.

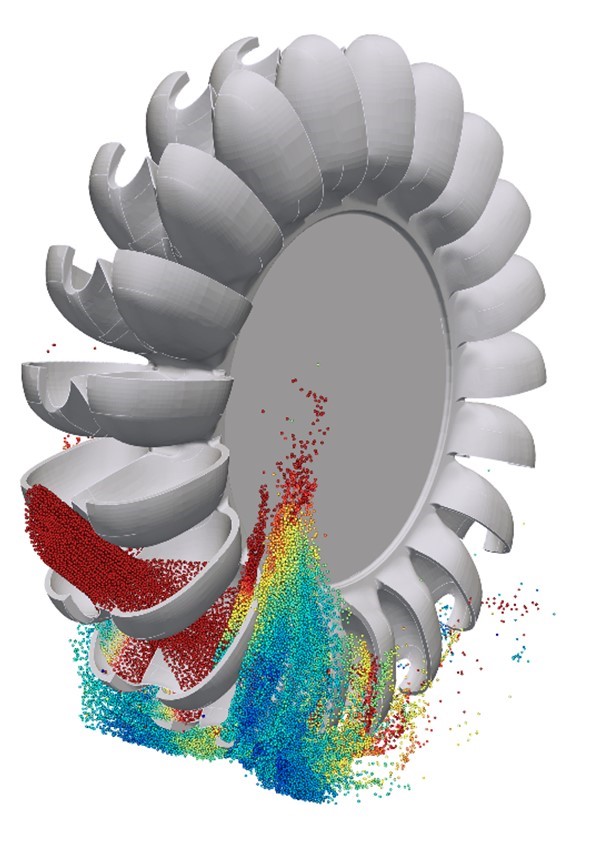

In the Pelton turbine, which is especially suited to plants with high heads, the water is directed by forming free jets at very high velocity from one or several nozzles to the Pelton runner. Until now, Pelton turbines with more than three nozzles have always been designed with a vertical shaft. The main reason for this was that it allowed higher efficiency than a horizontal arrangement.

Voith Hydro has now successfully eliminated this drawback, as demonstrated in the Gerlos 1 power plant, where for the first time, an efficiency level comparable to that of the vertical configuration has been achieved. The plant’s existing four vertical Pelton turbines were successfully replaced by one six-nozzle horizontal Pelton wheel.

Applications

In addition to this application, the technology is of particular interest for upgrades of existing hydropower plants where single- or double-nozzle horizontal units are already installed. This is because the turbine can be replaced without major structural works, which significantly reduces civil costs and installation times. At the same time, there is enormous potential for increasing efficiency. The associated potential reduction in the number of turbines can likewise lower future maintenance costs. The new development is also a winning solution for new systems, as it requires less excavation and is more compact with a smaller footprint than conventional solutions. This is also associated with a shorter installation time, which substantially reduces the overall investment costs.

Ongoing development work

The interaction between the water jet and the buckets of the Pelton wheel is extremely short, often just a few milliseconds. This is why the flow simulation of Pelton turbines is by far the most complex and difficult of all hydraulic turbomachinery simulations. Voith Hydro has refined the methods in recent years such that the housing flow can now also be analyzed. This important advance also made a significant contribution to the development of the new concept.

Since the beginning of the 20th century, Voith Hydro has supplied thousands of Pelton turbines in a wide range of sizes and outputs all over the world. For many years now, the company in Germany has been conducting intensive research on the concept of multi-nozzle, horizontal Pelton units. The resulting developments of all horizontal Pelton turbines with more than three nozzles are grouped under the designation “HP3+”.

Last year, Voith Hydro experts presented the technology at a leading hydropower conference in Vienna. This world premiere was preceded by extensive tests and pilot programs at the company’s own R&D center in Heidenheim. The first customers, including Austrian utility Verbund, are already using the innovative design.

About Gerlos 1

The Gerlos 1 power plant is a pumped storage facility in the Ziller Valley in Tyrol. Commissioned in 1949, it has an annual output of 326 GWh, allowing it to supply renewable energy to more than 70,000 four-person households.

Impressive transport operation

Even before the new unit was commissioned, the spectacular transport operation for the turbine housing was already causing a stir. At the beginning of April 2022, this 54-ton giant left the grounds of the Voith Hydro plant in St. Poelten, Austria. Apart from its weight, the dimensions of the unit were also impressive: just under nine meters long, more than six meters wide and over four meters high. This logistical masterstroke could be accomplished by means of a heavy transport operation taking an entire three nights.

Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Hydro is part of the Voith Group and a leading full line supplier as well as trusted partner for equipping hydropower plants. Voith develops customized, long-term solutions and services for large and small hydro plants all over the world. Its portfolio of products and services covers the entire life cycle and all major components for large and small hydro plants, from generators, turbines, pumps and automation systems, right through to spare parts, maintenance and training services, and digital

solutions for intelligent hydropower.

Loading of the 54-ton turbine housing at the Voith Hydro plant in St. Poelten

Special transport of the 6.5m wide turbine housing from St. Poelten to the Ziller Valley in Tyrol

Impressions from the Pelton test rig at Voith Hydro’s “Brunnenmühle” R&D Center in Germany

Modern flow simulation